Intuitive CMMS for the connected workforce

CHAMPS CMMS is a functionally comprehensive and advanced solution that allows organizations to manage and optimize their maintenance operations while increasing productivity.

Invest in your maintenance organization

CHAMPS Solutions

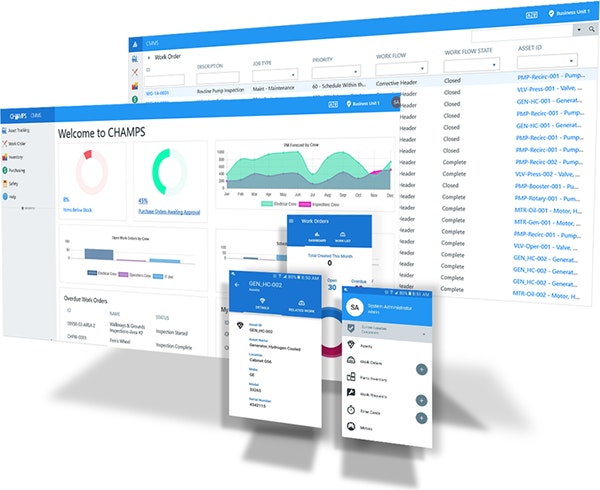

CMMS

CHAMPS CMMS is flexible and configurable. This enables users to leverage our solutions to match their unique maintenance processes. With ease of use features built in, users need minimal training to get started and become proficient in CHAMPS CMMS.

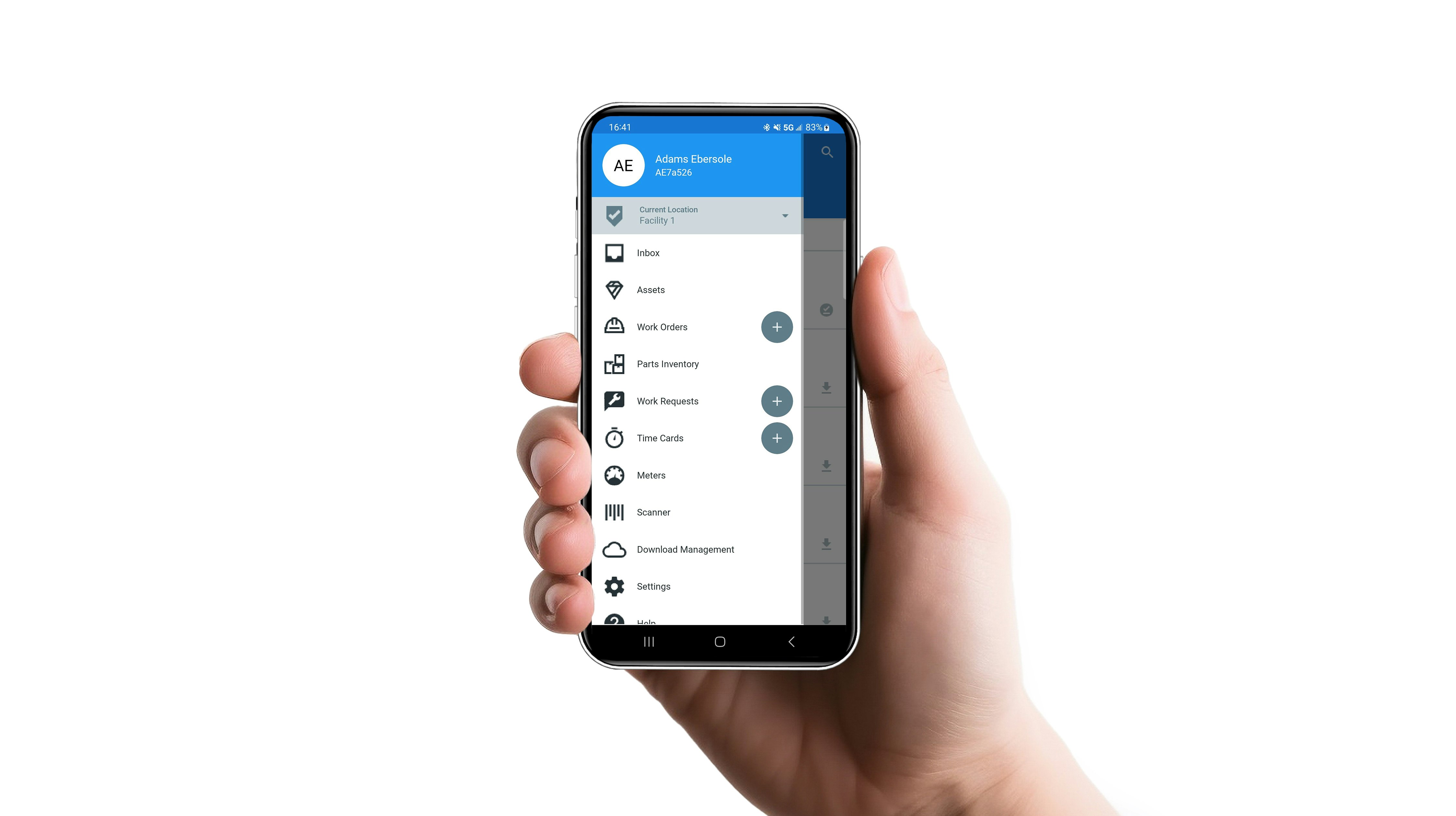

CHAMPS Mobile

Work smarter and faster with the right information, right when you need it with CHAMPS Mobile. Implementing our mobile work management solutions empowers your workforce while enhancing productivity.

SaaS

Fully accessible cloud based CMMS that allows your organization to automate tasks, track equipment and assets, and streamline communication and collaboration among maintenance teams. CHAMPS Saas is configurable and flexible to suit your company's needs.

Optional Modules

Customize your maintenance solutions with additional features such as Lockout/Tagout, Project Tracking and Permits.